If you’re a maintenance engineer, production manager, or someone grappling with optimizing factory operations, this article is for you! Join us on an inspiring journey through the digital transformation of Vietnamese businesses via EcoMaint CMMS Success Stories, showcasing Vietsoft’s cutting-edge maintenance management software. With over 20 years of expertise in manufacturing and maintenance, Vietsoft shares real-world case studies, impressive metrics, and valuable insights to demonstrate why EcoMaint CMMS is an indispensable partner for Vietnam’s manufacturing enterprises.

I. Why Manufacturers Need Digital Transformation in Maintenance Management

In the era of Industry 4.0, maintenance management has evolved beyond manual record-keeping and reactive problem-solving. Modern enterprises require intelligent, efficient systems to optimize equipment performance, reduce operational costs, and boost workforce productivity. Vietsoft’s EcoMaint CMMS addresses these needs, enabling businesses to shift from reactive maintenance to preventive and even predictive maintenance strategies.

Why is adopting a CMMS critical? Let’s explore common challenges faced by Vietnamese factories:

- Unexpected breakdowns disrupt production: Sudden equipment failures can halt production lines, resulting in losses worth millions of dollars.

- Escalating maintenance costs: Emergency repairs, excessive spare parts inventory, and rapid equipment wear inflate operational expenses.

- Inefficient manual processes: Relying on Excel or paper-based systems to manage hundreds of assets, maintenance schedules, and technicians often leads to errors and delays.

- Lack of actionable data: Without transparent data, managers struggle to identify high-cost equipment or recurring issues.

EcoMaint CMMS is more than software—it’s a comprehensive solution tackling these pain points. Let’s dive into EcoMaint CMMS Success Stories to uncover the tangible value it delivers.

II. Core Benefits of EcoMaint CMMS: Insights from Maintenance Experts

Before exploring real-world projects, let’s analyze the core benefits of EcoMaint CMMS from Vietsoft’s decades of maintenance expertise.

1. Boosting Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) is a critical metric for assessing factory performance. The formula is straightforward:

OEE = Availability × Performance × Quality

- Availability: EcoMaint CMMS enables preventive maintenance scheduling, slashing unplanned downtime. For instance, a production line with 12 hours of monthly downtime due to unexpected failures could reduce this to just 3 hours with EcoMaint.

- Performance: The software optimizes equipment speed and minimizes minor stoppages, boosting output.

- Quality: Properly maintained equipment ensures stable operation, reducing defective products and enhancing output quality.

Factories using EcoMaint often see OEE rise from 70% to 75% within six months, driving significant production and revenue gains.

2. Comprehensive Maintenance Cost Reduction

Maintenance costs extend beyond spare parts and labor to include downtime losses, excess inventory, and emergency repairs. EcoMaint delivers:

- Lower emergency repair costs: Preventive maintenance identifies issues early, preventing major failures. For example, replacing a failed motor might cost eight times more than replacing a small component during routine maintenance.

- Optimized spare parts inventory: Real-time inventory tracking and alerts prevent overstocking or shortages, cutting inventory costs by 15-25%.

- Extended equipment lifespan: Proper maintenance reduces wear and tear, delaying the need for costly replacements.

3. Enhanced Maintenance Team Productivity

EcoMaint automates maintenance workflows, from work order creation to task assignment and reporting. Technicians can:

- Access equipment details, repair histories, and checklists via mobile devices.

- Update task progress on-site, minimizing errors and administrative time.

What once took an hour to process manually now takes just five minutes with EcoMaint.

4. Data Transparency and Data-Driven Decisions

EcoMaint provides:

- Centralized data hub: Stores all equipment, maintenance, cost, and inventory data.

- Visual analytics: Intuitive charts and dashboards help managers identify bottlenecks and make informed decisions. For example, pinpoint which equipment incurs the highest costs or which issues recur frequently for targeted solutions.

These benefits are validated through numerous EcoMaint CMMS Success Stories across Vietnamese enterprises. Let’s examine a standout example.

III. EcoMaint CMMS Success Stories: Lam Viet Furniture Furniture’s Remarkable Results

Lam Viet Furniture Furniture, a leading Vietnamese furniture exporter, operates a single factory with five production workshops and over 800 specialized machines. Before EcoMaint, the company faced significant hurdles:

- Manual maintenance processes caused delays and errors.

- High unplanned downtime disrupted delivery schedules.

- Uncontrolled spare parts inventory led to inefficiencies.

1. Implementation Process

The EcoMaint CMMS deployment at Lam Viet Furniture was executed with precision and speed:

- November 28, 2023: Contract signed and project launched.

- January 15, 2024: System went live after just 48 days.

- March 1, 2024: Full operational stability achieved.

2. Project Scope:

- Managed over 800 assets across five workshops within one factory.

- Users: 3 executives, 15 maintenance engineers, and 65 production staff.

3. Results Achieved

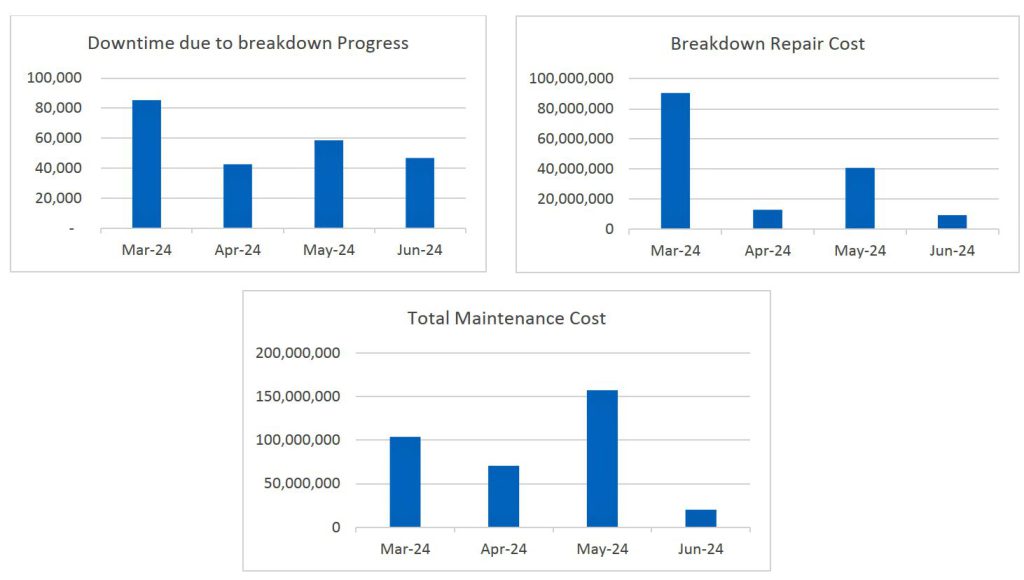

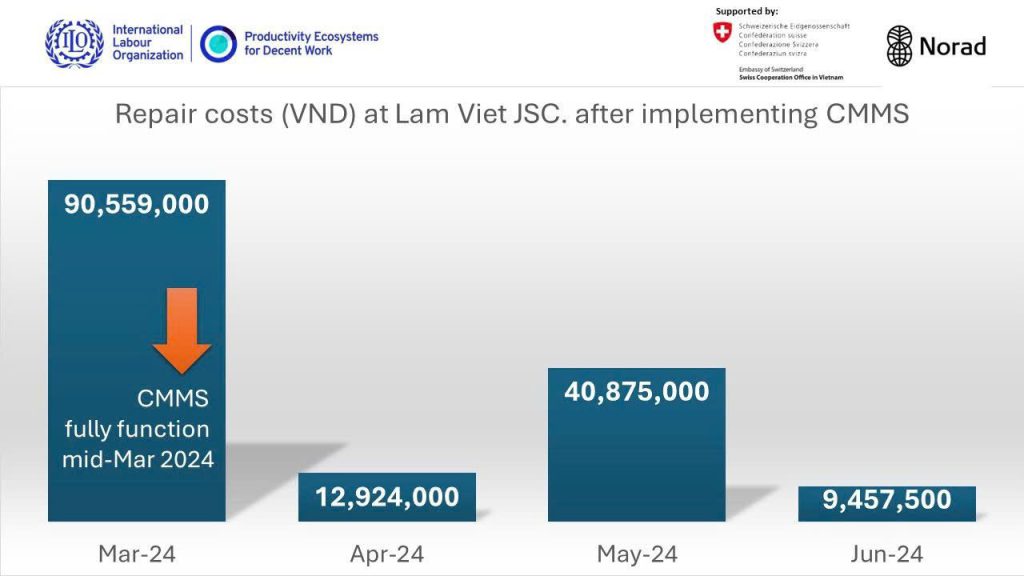

From March 1, 2024, to June 30, 2024, Lam Viet Furniture Furniture recorded impressive outcomes:

- 45% reduction in downtime: Saved 2,050 hours, equivalent to $20,500 (at $10/hour downtime cost).

- 22% reduction in total maintenance costs: Saved $3,200.

- 78% reduction in emergency repair costs: Preventive maintenance nearly eliminated major breakdowns.

- Total savings: $23,700 in four months, projecting annual savings of $94,800.

- Return on Investment (ROI): Achieved in just 3.5 months—an exceptional result!

4. Lessons from Lam Viet Furniture

- Prioritize preventive maintenance: Scheduled maintenance and condition monitoring minimized unexpected failures.

- Data integration: EcoMaint’s integration with the ERP system provided a holistic view of maintenance and production.

- Team training: Vietsoft’s training and user-friendly Vietnamese interface enabled rapid adoption by the workforce.

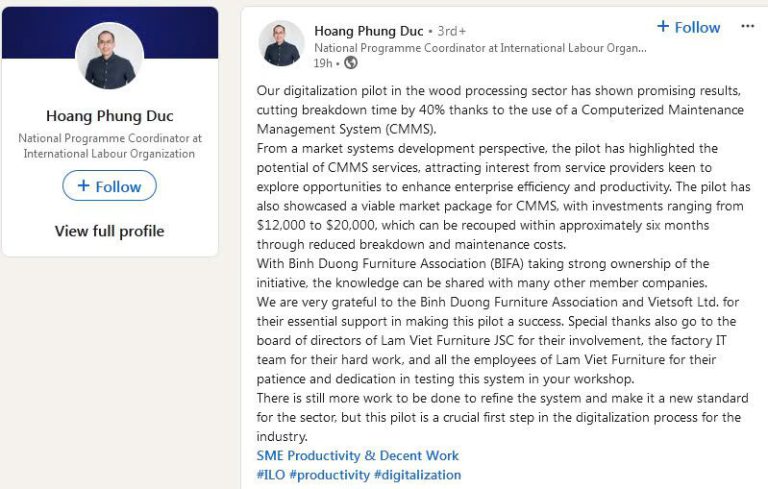

5. ILO Recognition and Insights

The International Labour Organization (ILO.org) representative, Hoang Phuong Duc, National Programme Coordinator, provided detailed feedback on the EcoMaint pilot at Lâm Việt Furniture. He noted that the digitalization initiative in the wood processing sector yielded promising results, reducing breakdown time by 40% and cutting costs between $12,000 and $20,000 within approximately six months. From a market development perspective, the pilot highlighted the potential of CMMS services, attracting interest from service providers eager to enhance efficiency and productivity. The pilot also showcased a viable package for CMMS, with investments ranging from $12,000 to $20,000, which could be recouped within six months through reduced downtime and maintenance costs.

The ILO expressed gratitude to Binh Duong Furniture Association and Vietsoft Ltd. for their essential support in making the pilot a success, extending special thanks to the Lam Viet Furniture factory IT team for their hard work, patience, and dedication in testing the system in the workshop. This pilot marks a crucial first step in the digitalization process for the industry’s productivity and decent work.

IV. More EcoMaint CMMS Success Stories: Transformative Outcomes

Beyond Lam Viet Furniture, Vietsoft has empowered numerous manufacturers with EcoMaint, each achieving unique results:

- Nakydaco: Reduced downtime by 28%, saved 12% on maintenance costs, and boosted productivity by 18%.

- VINA ONE STEEL: Lowered excessive maintenance costs and enabled real-time asset tracking.

- TRUNG NGUYEN LEGEND: Cut downtime by 15-22%, optimized spare parts inventory by 8%, and extended equipment life by 12%.

- LOTTE Chemical Vietnam: Standardized maintenance processes, ensuring industry compliance.

- Terumo Vietnam: Optimized asset performance, reduced downtime by 18%, and enhanced data-driven decisions.

These figures underscore the transformative power of EcoMaint CMMS Success Stories, inspiring other businesses to embrace digital transformation.

V. Deep Maintenance Insights: Lessons from EcoMaint CMMS Success Stories

From these proven case studies, we can extract key lessons for managers and maintenance teams:

1. Preventive and predictive maintenance are key: Shifting from reactive to proactive maintenance reduces costs and enhances efficiency.

· Asset management is foundational: A well-organized asset hierarchy ensures effective CMMS performance.

· Spare parts inventory optimization: Balancing inventory costs and availability is critical to cost savings.

· Data’s transformative power: Collecting and analyzing maintenance data enables trend identification and predictive maintenance.

· Cultural shift through digitalization: EcoMaint fosters collaboration and drives a digital-first mindset within organizations.

VI. Why EcoMaint is the Top Choice for Vietnamese Manufacturers

With over two decades of experience in Vietnam, Vietsoft offers more than software—it delivers tailored solutions. Here’s why EcoMaint stands out:

- Deep market understanding: Designed with Vietnamese workflows in mind, featuring a user-friendly Vietnamese interface and high customizability.

- Scalable and flexible: Suitable for small businesses or multi-site corporations, with cloud or on-premise deployment and seamless ERP/IoT integration.

- End-to-end support: From consultation to training and post-implementation support, Vietsoft ensures maximum value.

- Continuous innovation: EcoMaint integrates AI and IoT, aligning with Industry 4.0 and future demands.

VII. Discover EcoMaint CMMS Today!

Ready to end the cycle of chasing breakdowns, reduce maintenance costs, and build a stable, efficient factory? Vietsoft EcoMaint is a leading CMMS solution, enabling manufacturing enterprises to manage maintenance scientifically and efficiently. With over 20 years of digital transformation experience, Vietsoft delivers a tool that supports preventive and predictive maintenance, minimizing downtime and optimizing operational costs.

Explore the CMMS EcoMaint solution here. Contact us for consultation via hotline: 0986778578 or email: sales@vietsoft.com.vn.

Don’t let maintenance challenges hinder your growth.