In the world of industrial maintenance, selecting the right software can transform how businesses manage their assets and operations. Two prominent solutions often come up: CMMS vs EAM Software. But what exactly do these terms mean, and how do they differ?

I. What is CMMS?

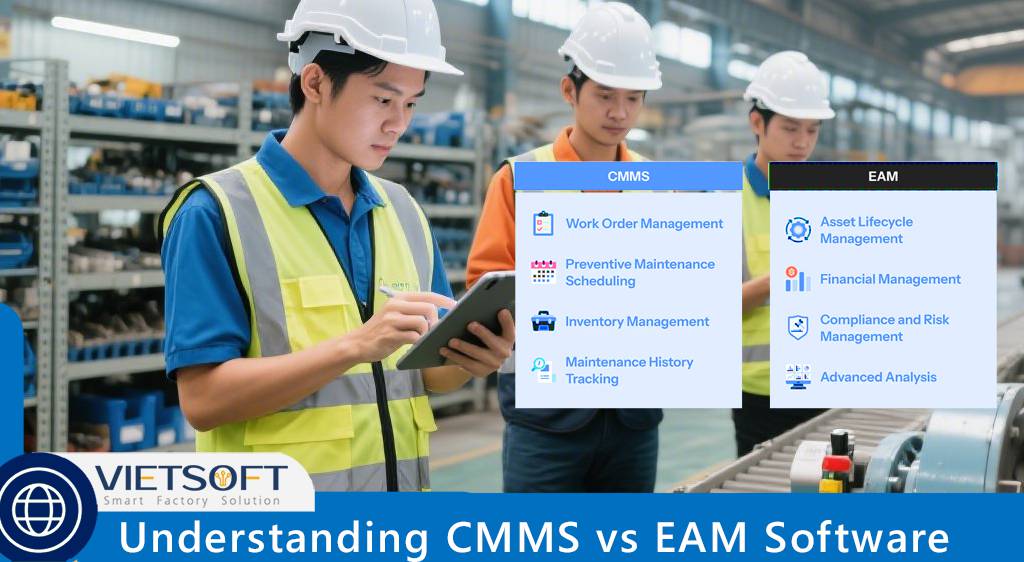

A Computerized Maintenance Management System (CMMS) is a specialized digital tool designed to streamline maintenance operations. It serves as a central hub for scheduling tasks, tracking work orders, managing inventory, and maintaining detailed records of equipment upkeep. For maintenance teams, CMMS acts like a reliable assistant, ensuring assets remain operational by automating routine tasks and providing real-time insights.

Imagine a factory where technicians juggle multiple machines daily. A CMMS like EcoMaint helps them schedule preventive maintenance, log repairs, and monitor spare parts—all from one platform. This focus on maintenance efficiency makes CMMS a go-to for teams looking to reduce downtime and enhance productivity.

II. What is EAM?

Enterprise Asset Management (EAM) software takes a broader approach, overseeing the entire lifecycle of assets—from procurement to retirement. It’s a strategic tool that integrates maintenance with other business functions like finance, procurement, and compliance. EAM is akin to a comprehensive asset orchestra conductor, ensuring every stage of an asset’s life is optimized.

For large organizations managing complex asset portfolios—such as power plants or transportation fleets—EAM provides a holistic view. It tracks everything from initial purchase costs to depreciation, making it ideal for industries where assets are critical to long-term success.

III. Key Differences Between CMMS and EAM Software

Understanding the nuances of CMMS vs EAM Software is crucial for choosing the right fit. Let’s break it down based on practical parameters that matter to maintenance professionals.

1. Primary Focus and Scope

- CMMS: Centers on maintenance management, covering work orders, preventive maintenance, and equipment performance. Its scope is maintenance-centric, perfect for teams needing to keep operations running smoothly.

- EAM: Encompasses full asset lifecycle management, from acquisition to disposal. This enterprise-wide scope integrates with HR, finance, and procurement, offering a big-picture view for cross-departmental oversight.

2. Best Use Cases

- CMMS: Ideal for companies seeking to boost maintenance visibility and efficiency. Small to mid-sized businesses or those with focused asset needs thrive with CMMS.

- EAM: Suited for large enterprises managing diverse assets across multiple sites, such as utilities or manufacturing giants needing strategic asset oversight.

3. Complexity and Learning Curve

- CMMS: Offers lower complexity, making it easier to adopt and use. Technicians can quickly learn the system, reducing training time.

- EAM: Comes with higher complexity and a steeper learning curve, requiring more training and buy-in from various departments.

4. Scalability and Deployment

- CMMS: Highly scalable across teams and sites, with faster deployment (often within weeks) and lower total cost of ownership.

- EAM: Scalable but demands heavier infrastructure, with longer implementation cycles (months) and higher costs due to its comprehensive nature.

5. Advanced Capabilities

- CMMS: Includes analytics, multi-site support, and inspection tools, catering to growing maintenance needs.

- EAM: Adds compliance tracking, financial planning, and procurement management, supporting strategic decision-making.

IV. Feature Comparison: CMMS vs EAM Software

To give you a clearer picture, here’s how CMMS vs EAM Software stacks up in terms of features, based on real-world maintenance needs:

Feature Comparison: CMMS vs EAM Software

|

Feature |

CMMS |

EAM |

|

Asset Register |

No |

Yes |

|

Asset Tracking |

Yes |

Yes (Multi-site) |

|

Asset Lifecycle Management |

No |

Yes |

|

Condition Monitoring |

Yes |

Yes (Advanced Sensor Integration) |

|

Document Management |

Optional (Add-ons) |

Yes |

|

Energy Monitoring |

No |

Yes |

|

Fleet Management |

No |

Yes |

|

Inventory Management |

Yes |

Yes (Broader Integration) |

|

Preventive Maintenance |

Yes |

Yes |

|

Project Management |

No |

Yes |

|

Reporting |

Yes |

Yes (Deeper Analytics) |

|

Safety & Compliance |

Basic |

Yes |

|

Spare Parts Management |

Yes |

Yes |

|

Work Order Management |

Yes |

Yes |

|

Work Planning |

Yes |

Yes (Strategic) |

V. Practical Applications and Benefits

1. When to Choose CMMS

For maintenance professionals, CMMS shines in scenarios where the goal is to enhance daily operations. Consider these benefits:

- Reducing Unplanned Downtime: Schedule preventive maintenance to keep critical machinery running.

- Cost Savings: Lower repair costs by addressing issues early.

- Safety Improvement: Ensure compliance with safety standards through regular checks.

- Asset Longevity: Extend equipment life with proactive care.

2. When to Choose EAM

EAM is the choice for organizations with complex asset portfolios. Its advantages include:

- Lifecycle Optimization: Track assets from purchase to disposal, maximizing value.

- Cost Control: Monitor total ownership costs, including energy and depreciation.

- Strategic Insights: Use data for future procurement and investment decisions.

- Regulatory Adherence: Maintain compliance across multiple sites.

VI. Implementation Considerations

1. CMMS Deployment

Implementing CMMS is straightforward. Start by inputting asset details and setting up maintenance schedules. The system can be live in weeks, with minimal IT overhead. For instance, a technician can log a work order in minutes, and managers can track progress in real time.

2. EAM Deployment

EAM requires a phased approach, integrating with existing ERP systems and training cross-functional teams. This process may take months but ensures a unified asset strategy. A transportation firm might spend three months aligning EAM with its fleet and finance departments for seamless operation.

VII. Measuring Success

Evaluating the effectiveness of CMMS vs EAM Software is essential to ensure that your investment delivers tangible benefits. By tracking specific metrics, maintenance professionals can assess performance, optimize processes, and justify the use of these systems. Below, we dive deeper into the key metrics for both CMMS and EAM, providing detailed explanations and practical examples to guide your analysis.

1. CMMS Metrics

CMMS focuses on enhancing day-to-day maintenance operations, and its success can be measured through metrics that reflect cost efficiency and activity management. These metrics are particularly valuable for teams looking to streamline workflows and reduce operational disruptions.

Asset-Related Cost

This metric involves tracking all expenses associated with maintaining assets, including repair costs, parts procurement, and any associated labor charges. By monitoring these costs, maintenance managers can identify trends, such as recurring issues with specific equipment, and allocate budgets more effectively. For instance, a sudden spike in parts expenses might indicate a need for better preventive maintenance or a potential equipment failure.

Practical Application: A manufacturing plant using CMMS might notice that repair costs for a conveyor belt have risen by 20% over three months due to frequent breakdowns. By analyzing this data, the team can schedule more regular inspections to address underlying issues, potentially saving thousands in emergency repairs.

Asset-Related Activity

This metric tracks the frequency and duration of maintenance activities, such as work orders, inspections, and repairs. It provides insight into how often assets require attention and how long tasks take, helping teams optimize scheduling and improve technician productivity. High frequency with short durations might indicate effective preventive maintenance, while prolonged durations could signal inefficiencies or complex issues.

Practical Application: A facility manager might use CMMS to log that a pump requires maintenance every two weeks, with each task taking an average of 2 hours. Over a year, this equates to 26 maintenance events totaling 52 hours. By analyzing this, the manager could adjust the maintenance schedule to every three weeks, reducing downtime by approximately 17 hours annually.

Formula: Total Maintenance Cost = (Labor Cost + Parts Cost) / Number of Assets

This formula provides a per-asset cost overview, enabling comparisons across different equipment or sites. For example, if a company spends $10,000 on labor and $5,000 on parts to maintain 50 assets, the total maintenance cost per asset is ($10,000 + $5,000) / 50 = $300. This figure can guide budget planning and highlight areas for cost reduction, such as bulk purchasing parts or training staff to reduce labor hours.

2. EAM Metrics

EAM takes a strategic approach, focusing on the long-term value and reliability of assets across their entire lifecycle. Its metrics are designed for organizations managing complex, high-value assets, offering a broader perspective on performance and financial impact.

Asset Value

This metric assesses the current and depreciated worth of assets, providing a clear picture of their financial status over time. It includes the original purchase price minus depreciation, adjusted for maintenance investments or market changes. Understanding asset value helps managers make informed decisions about repairs, replacements, or upgrades, ensuring optimal return on investment.

Practical Application: A utility company using EAM might calculate that a turbine, originally costing $1 million with a 10-year lifespan, has a depreciation rate of 10% annually. After 5 years, the asset value remaining is $1,000,000 – (0.10 × $1,000,000 × 5) = $500,000. If maintenance costs exceed the remaining value, the company might consider replacement to avoid further losses.

Asset Stability

This metric evaluates uptime and reliability, critical for assets that support continuous operations. It measures how consistently an asset performs without failures, factoring in downtime incidents and maintenance interventions. High stability indicates a robust maintenance strategy, while frequent disruptions may suggest the need for predictive tools or equipment upgrades.

Practical Application: A transportation firm using EAM might track a fleet vehicle with 95% uptime over a month, meaning it was operational for 456 hours out of 480 possible hours. A sudden drop to 85% uptime could trigger an investigation into maintenance logs, revealing a need for enhanced condition monitoring to prevent future issues.

Formula: Asset Value Remaining = Original Cost – (Depreciation Rate × Years Used)

This formula calculates the residual value of an asset, aiding in lifecycle management decisions. For instance, a machine with an original cost of $200,000, a 5% annual depreciation rate, and 3 years of use would have a remaining value of $200,000 – (0.05 × $200,000 × 3) = $170,000. This data can inform whether to continue maintaining the asset or invest in a new one.

3. Leveraging Metrics for Decision-Making

Both CMMS and EAM metrics empower maintenance teams to move from reactive to proactive management. For CMMS users, regular cost and activity reviews can refine preventive maintenance schedules, while EAM users can use value and stability data to align asset strategies with business goals. By integrating these metrics into dashboards—available in advanced CMMS and EAM platforms—teams can visualize trends, set benchmarks, and drive continuous improvement.

For example, a maintenance supervisor might use CMMS data to reduce per-asset costs by 15% through better parts inventory management, while an EAM manager might extend asset stability by 10% with predictive maintenance, saving millions in downtime costs. These measurable outcomes underscore the importance of selecting the right system based on your specific metrics focus.

VIII. Advanced Insights: Technology Platforms

1. CMMS Technology

CMMS platforms focus on scheduling and reporting, automating maintenance for field teams. They use basic integrations to enhance communication, making them accessible for smaller operations.

2. EAM Technology

EAM leverages data across the asset lifecycle, integrating with IoT and ERP systems. This enables predictive maintenance and operational infrastructure support for large enterprises.

3. APM Technology

Asset Performance Management (APM) builds on EAM, using analytics to predict failures and optimize performance. It’s ideal for high-value assets in manufacturing or energy sectors.

Choosing the Right Solution for Your Business

Selecting between CMMS vs EAM Software depends on your organization’s size, asset complexity, and goals. Small businesses with 50-100 assets may find CMMS sufficient, while enterprises with thousands of assets across sites benefit from EAM. Conduct a needs assessment: How many assets do you manage? What are your downtime costs? Engage with vendors for demos to test usability.

IX. Introducing CMMS EcoMaint by Vietsoft

For businesses in Vietnam seeking a tailored maintenance solution, exploring the deployment of CMMS EcoMaint by Vietsoft could be a game-changer. This innovative software, designed with local market insights, streamlines maintenance processes while offering scalability for growth. Curious about how it can transform your operations? Discover the CMMS EcoMaint solution here.

Contact us for consultation via hotline: 0986778578 or email: sales@vietsoft.com.vn.

X. Conclusion

Navigating CMMS vs EAM Software requires understanding your maintenance needs and long-term strategy. Whether you opt for the focused efficiency of CMMS or the comprehensive oversight of EAM, the right choice boosts productivity and reduces costs. For expert guidance, consider testing solutions like CMMS EcoMaint to see the difference in action.