Facility Condition Assessment (FCA) is a cornerstone of effective facility management, offering a structured approach to evaluating and maintaining the health of physical assets. Whether you’re a facility manager, property owner, or maintenance professional, understanding how to conduct a thorough FCA can transform your maintenance strategy, reduce costs, and ensure compliance.

This comprehensive guide explores the intricacies of the Facility Condition Assessment (FCA) Checklist, its applications and benefits.

I. What is a Facility Condition Assessment (FCA)?

A Facility Condition Assessment (FCA) is a systematic process that evaluates the physical condition, performance, and operational efficiency of a facility’s components and systems. It goes beyond routine inspections by providing a data-driven snapshot of a building’s health, covering structural elements, mechanical systems, electrical infrastructure, and more. The FCA Checklist serves as a roadmap, guiding assessors to identify issues, prioritize maintenance tasks, and plan for long-term asset care.

The primary goal of an FCA is to quantify the condition of a facility to inform maintenance decisions, optimize budgets, and ensure safety and compliance. By leveraging standardized methodologies and objective metrics like the Facility Condition Index (FCI), an FCA empowers stakeholders to make informed, strategic decisions.

II. Why is FCA Critical for Facility Management?

The importance of Facility Condition Assessment lies in its ability to prevent costly breakdowns, extend asset lifespans, and align maintenance with organizational goals. For industries like manufacturing, healthcare, and education in Vietnam, where operational uptime and safety are paramount, FCAs are indispensable. They provide actionable insights that help facility managers avoid reactive repairs, plan capital investments, and maintain a safe environment for occupants.

III. The Role of the FCA Checklist in Maintenance Management

The FCA Checklist is a structured tool that ensures no critical component is overlooked during an assessment. It standardizes the evaluation process, enabling consistent data collection and analysis. By covering all major facility systems—structural, mechanical, electrical, and safety—the checklist helps facility managers prioritize tasks, estimate costs, and align maintenance with regulatory and operational requirements.

IV. Key Components of an FCA Checklist

A robust FCA Checklist includes:

- Asset Inventory: A detailed list of all facility assets, including equipment, structural components, and utilities.

- Condition Evaluation: Assessing the physical state of assets for wear, damage, or inefficiencies.

- Code Compliance Check: Verifying adherence to local safety, environmental, and building regulations.

- Cost Estimation: Calculating repair, replacement, or upgrade costs for budgeting purposes.

- Prioritization: Ranking maintenance tasks based on urgency, impact, and resource availability.

- Energy Efficiency Review: Identifying opportunities to reduce energy consumption and improve sustainability.

This checklist ensures a thorough and repeatable process, making it easier to track facility conditions over time and implement data-driven maintenance strategies.

V. The FCA Process: A Step-by-Step Approach

Conducting a Facility Condition Assessment involves a structured, multi-stage process designed to deliver actionable insights. Below is a detailed breakdown of the key steps:

1. Step 1: Pre-Assessment Preparation

Before the physical inspection begins, preparation is critical. This involves:

- Gathering Documentation: Collect architectural drawings, maintenance logs, equipment manuals, and past FCA reports. These documents provide context on the facility’s history and maintenance practices.

- Defining Objectives: Establish clear goals, such as identifying safety hazards, assessing compliance, or planning capital improvements.

- Leveraging Technology: Tools like CMMS EcoMaint, developed by Vietsoft, centralize documentation and streamline the planning process by storing asset data and maintenance histories in one accessible platform.

2. Step 2: On-Site Inspection

The on-site inspection involves a multidisciplinary team of experts, including structural engineers, HVAC specialists, and electricians. Key activities include:

- Visual and Technical Inspections: Examine structural components (e.g., walls, roofs, foundations), mechanical systems (e.g., HVAC, plumbing), and safety systems (e.g., fire alarms, emergency exits).

- Data Collection: Use mobile apps, sensors, and cameras to record findings. CMMS EcoMaint’s mobile interface allows inspectors to log data in real time, reducing errors and paperwork.

- Standardized Scoring: Assign condition ratings (e.g., excellent, good, fair, poor) to quantify asset health.

3. Step 3: Data Analysis and Scoring

Once data is collected, it’s analyzed to prioritize maintenance needs:

- Asset Prioritization: Identify critical assets that impact safety, compliance, or operations.

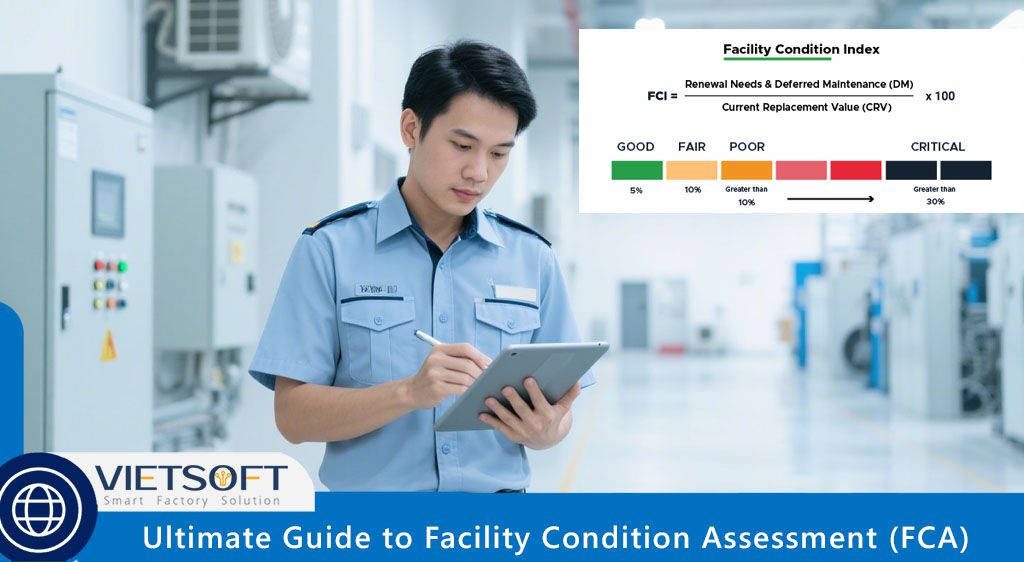

- Facility Condition Index (FCI): Calculate the FCI using the formula:

FCI = (Total Cost of Existing Deficiencies / Current Replacement Value) × 100

For example, if a building requires $500,000 in repairs and its replacement value is $5,000,000, the FCI is 10%, indicating a “fair” condition. - Trend Analysis: Use historical data to identify patterns of deterioration or recurring issues.

4. Step 4: Reporting and Recommendations

The FCA report consolidates findings into a comprehensive document, including:

- Executive Summary: A high-level overview of the facility’s condition.

- Asset Inventory and Condition Scores: Detailed ratings for each system or component.

- Cost Estimates: Budget projections for repairs, replacements, or upgrades.

- Visual Documentation: Photos and diagrams to illustrate findings.

- Action Plan: Prioritized recommendations for immediate and long-term maintenance.

CMMS EcoMaint simplifies report generation by automating data compilation and integrating visuals directly into asset records.

5. Step 5: Implementation and Follow-Up

The final step involves acting on the FCA recommendations:

- Prioritize Repairs: Address critical issues like safety hazards or code violations first.

- Budget Planning: Allocate funds for short-term fixes and long-term capital projects.

- Ongoing Monitoring: Use CMMS EcoMaint to track maintenance progress, schedule follow-up inspections, and update asset records.

VI. Benefits of Conducting Regular Facility Condition Assessments

Regular FCAs deliver measurable benefits for facility managers, property owners, and stakeholders. These include:

1. Cost Savings Through Proactive Maintenance

- Preventive Maintenance: Identifying issues early, such as a leaking roof or a failing HVAC unit, prevents costly emergency repairs. For example, fixing a minor roof leak might cost $1,000, while water damage from an unchecked leak could exceed $50,000.

- Extended Asset Lifespan: Regular maintenance extends the life of assets, delaying expensive replacements. A well-maintained HVAC system can last 15–20 years instead of 10.

2. Enhanced Safety and Compliance

- Occupant Safety: FCAs identify hazards like faulty wiring or blocked emergency exits, ensuring a safe environment for employees, visitors, and customers.

- Regulatory Compliance: Assessments verify adherence to Vietnam’s building codes, fire safety regulations, and environmental standards, reducing the risk of fines or legal issues.

3. Improved Budget Planning

- Accurate Forecasting: FCA data helps create realistic maintenance budgets, avoiding unexpected costs. For instance, knowing a boiler will need replacement in three years allows for phased financial planning.

- Resource Allocation: Prioritize spending on critical systems, ensuring efficient use of limited budgets.

4. Sustainability and Energy Efficiency

- Energy Savings: FCAs identify opportunities to upgrade to energy-efficient systems, such as LED lighting or optimized HVAC units, reducing utility costs by up to 20–30%.

- Green Compliance: Align with Vietnam’s growing emphasis on sustainable building practices, including compliance with standards like LOTUS (Vietnam’s green building certification).

5. Strategic Decision-Making

- Capital Planning: FCAs inform long-term investments, such as whether to repair or replace aging equipment.

- Portfolio Management: For organizations managing multiple facilities, FCAs provide a standardized metric (FCI) to compare asset conditions and prioritize investments.

VI. Industries and Facilities That Benefit from FCAs

Facility Condition Assessments are vital across various sectors in Vietnam, where diverse facilities require tailored maintenance strategies:

- Manufacturing: Factories rely on FCAs to ensure machinery and infrastructure operate reliably, minimizing production downtime.

- Healthcare: Hospitals use FCAs to maintain sterile, safe environments, ensuring compliance with strict health regulations.

- Education: Schools and universities leverage FCAs to create safe, functional learning spaces.

- Commercial Real Estate: Property owners use FCAs to assess investment properties, informing purchase or sale decisions.

- Hospitality: Hotels and resorts conduct FCAs to enhance guest safety and satisfaction, maintaining competitive edge.

- Government: Public buildings, like courthouses or libraries, use FCAs to manage taxpayer-funded assets efficiently.

VII. Trends Shaping Facility Condition Assessments in 2025

As facility management evolves, so do FCA practices. Key trends influencing FCAs in 2025 include:

1. Digital Transformation

- IoT and Sensors: Real-time monitoring of asset conditions using IoT devices reduces manual inspections and improves accuracy.

- Mobile Apps: Tools like CMMS EcoMaint enable inspectors to log data on-site, streamlining workflows and reducing errors.

- AI and Predictive Analytics: AI-driven insights predict maintenance needs, allowing proactive interventions before failures occur.

2. Sustainability Focus

- Green Assessments: FCAs increasingly evaluate environmental impact, such as carbon footprints and energy efficiency, aligning with global sustainability goals.

- Renewable Energy Integration: Assessments explore opportunities to incorporate solar panels or other renewable energy sources, especially in Vietnam’s push for green infrastructure.

3. Regulatory Evolution

- Stricter Compliance: Vietnam’s updated building codes and environmental regulations require FCAs to include detailed compliance checks.

- Data Transparency: Stakeholders demand comprehensive FCA reports to demonstrate due diligence and regulatory adherence.

4. Integration with CMMS Platforms

Modern FCAs are tightly integrated with Computerized Maintenance Management Systems (CMMS). Vietsoft’s CMMS EcoMaint, for example, centralizes FCA data, automates work order generation, and tracks maintenance progress, ensuring seamless implementation of assessment recommendations.

VIII. Challenges in Conducting Facility Condition Assessments

Despite their benefits, FCAs present challenges that require strategic solutions:

1. Data Accuracy and Consistency

- Inconsistent Data Sources: Discrepancies in maintenance records or asset documentation can skew FCA results. Solution: Use CMMS EcoMaint to centralize and standardize data.

- Human Error: Manual inspections are prone to oversight. Solution: Leverage mobile apps and automated tools to ensure precision.

2. Budget Constraints

- Competing Priorities: Limited budgets may force organizations to defer maintenance. Solution: Use FCA data to justify funding for critical repairs.

- Cost-Benefit Analysis: Balancing immediate repair costs with long-term savings is complex. Solution: Conduct lifecycle cost analyses to inform decisions.

3. Technology Adoption

- Learning Curve: Implementing new FCA tools requires training. Solution: Choose user-friendly platforms like CMMS EcoMaint with intuitive interfaces and local support in Vietnam.

- Integration Complexity: Merging FCA data with existing systems can be challenging. Solution: Opt for scalable CMMS solutions with robust integration capabilities.

IX. Best Practices for Effective Facility Condition Assessments

To maximize the value of FCAs, facility managers should adopt these best practices:

1. Schedule Regular Assessments

- Conduct FCAs every 3–5 years, or more frequently for high-use facilities like hospitals or factories.

- Schedule inspections during low-occupancy periods to minimize disruption.

2. Leverage Technology

- Use CMMS EcoMaint to streamline data collection, storage, and reporting.

- Incorporate IoT sensors for real-time asset monitoring and predictive maintenance.

3. Engage Qualified Professionals

- Assemble a multidisciplinary team with expertise in structural engineering, HVAC, and electrical systems.

- Provide ongoing training to keep assessors updated on industry standards and technologies.

4. Prioritize Sustainability

- Include energy efficiency and environmental impact in FCA checklists.

- Align assessments with green building standards like LOTUS to enhance sustainability credentials.

5. Integrate with Facility Management

- Link FCA findings to daily maintenance workflows via CMMS EcoMaint.

- Use predictive analytics to forecast maintenance needs and optimize resource allocation.

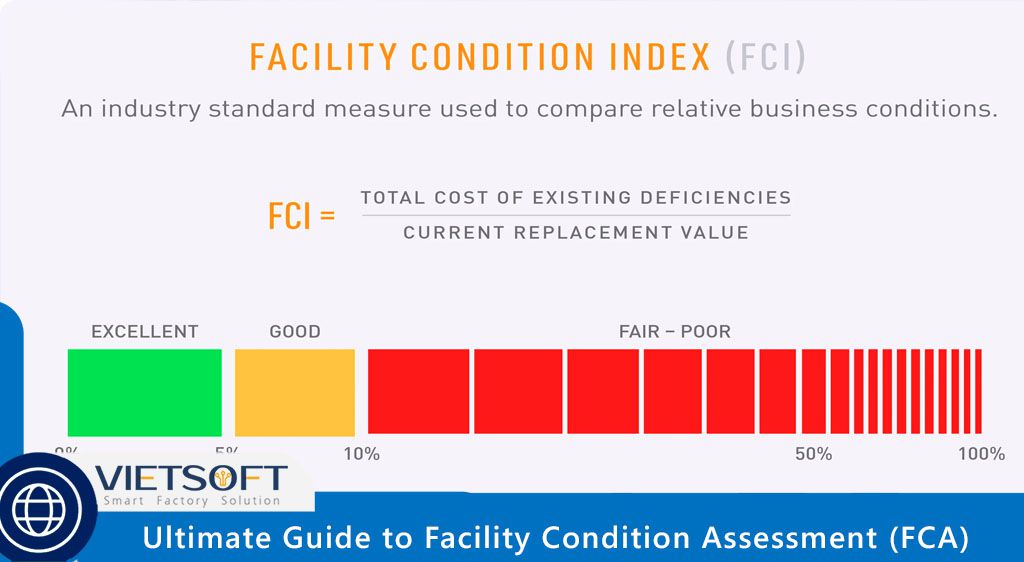

X. Facility Condition Index (FCI): A Key Metric

The Facility Condition Index (FCI) is a critical metric for benchmarking facility health. It is calculated as:

FCI = (Total Cost of Existing Deficiencies / Current Replacement Value) × 100

FCI Scale:

- 0–5%: Excellent condition, minimal maintenance needed.

- 5–10%: Good condition, routine maintenance sufficient.

- 10–30%: Fair condition, requires prioritized repairs.

- 30%+: Poor condition, consider major renovations or replacement.

For example, a factory with $200,000 in repair needs and a $4,000,000 replacement value has an FCI of 5%, indicating good condition but requiring proactive maintenance to prevent deterioration.

XI. How CMMS EcoMaint Enhances FCA Processes

Vietsoft’s CMMS EcoMaint is a game-changer for Facility Condition Assessments, offering a robust platform to streamline every stage of the process. Designed with Vietnam’s industrial and commercial sectors in mind, EcoMaint provides:

- Centralized Data Management: Store asset inventories, maintenance logs, and FCA reports in one secure platform.

- Mobile Data Collection: Log inspection data on-site using EcoMaint’s mobile app, reducing errors and paperwork.

- Automated Reporting: Generate professional FCA reports with condition scores, cost estimates, and prioritized recommendations.

- Predictive Maintenance: Use historical FCA data to forecast maintenance needs and prevent costly failures.

- Local Support: Vietsoft’s expertise in Vietnam’s maintenance landscape ensures tailored solutions for local regulations and industry needs.

By integrating FCA findings into daily operations, CMMS EcoMaint empowers facility managers to act swiftly on recommendations, optimize budgets, and maintain compliance. Curious about how EcoMaint can transform your maintenance strategy? Learn more about CMMS EcoMaint here.

Contact us for consultation via hotline: 0986778578 or email: sales@vietsoft.com.vn.

XII. Conclusion

The Facility Condition Assessment (FCA) Checklist is an essential tool for maintaining safe, efficient, and sustainable facilities. By providing a structured approach to evaluating asset conditions, prioritizing repairs, and planning budgets, FCAs empower facility managers to make data-driven decisions that enhance operational reliability and reduce costs. In Vietnam’s fast-growing industrial and commercial landscape, tools like CMMS EcoMaint by Vietsoft amplify the value of FCAs, offering seamless data management, predictive maintenance, and compliance tracking.

Ready to elevate your facility management strategy? Start implementing regular FCAs with a comprehensive checklist and explore how CMMS EcoMaint can streamline your processes. Visit Vietsoft’s CMMS EcoMaint page to learn how this powerful tool can transform your maintenance operations, ensuring your facilities remain in top condition for years to come.