In today’s fast-paced industrial landscape, minimizing downtime and optimizing equipment performance are critical for success. Whether you’re managing a manufacturing plant or overseeing technical systems, understanding key maintenance metrics like MTBF, MTTF, MTTR, and MTTA can transform how you approach asset management and incident response. These metrics provide a window into the reliability, responsiveness, and efficiency of your operations, helping maintenance teams make informed decisions to keep systems running smoothly. Let’s dive into what these terms mean, how they differ, and why they matter—especially from the perspective of a seasoned industrial maintenance expert.

I. What Are MTBF, MTTF, MTTR, and MTTA?

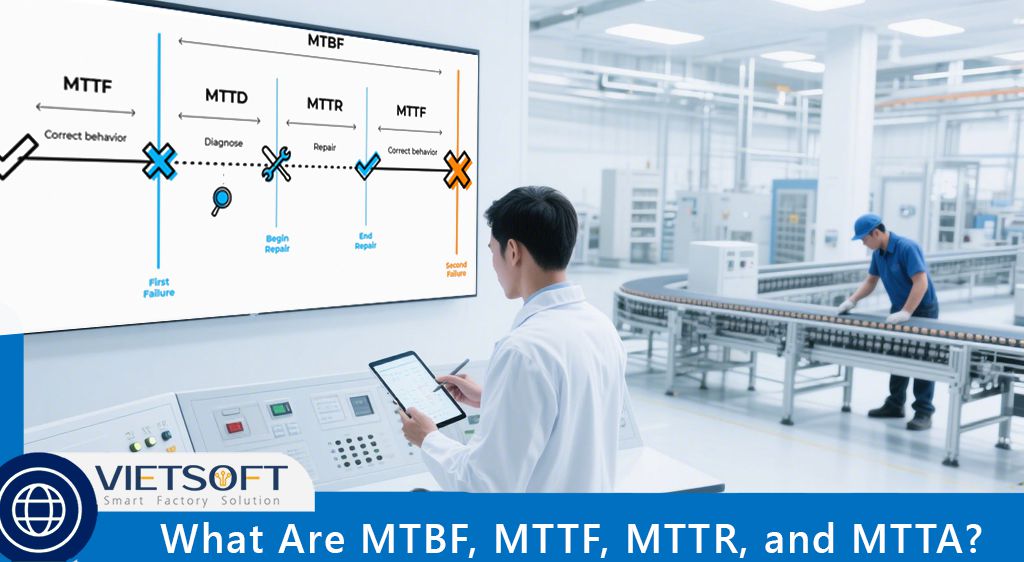

These acronyms—MTBF (Mean Time Between Failures), MTTF (Mean Time to Failure), MTTR (Mean Time to Repair, Recovery, Respond, or Resolve), and MTTA (Mean Time to Acknowledge)—are critical performance indicators in incident management and maintenance. They quantify how often systems fail, how quickly teams respond, and how effectively issues are resolved. In an era where outages lead to missed deadlines, delayed payments, and project setbacks, these metrics empower teams to track uptime, downtime, and recovery efficiency, fostering a proactive approach to asset management.

While some argue these metrics alone don’t address the “why” or “how” of incident resolution, they provide a solid foundation for deeper analysis. They spark conversations about root causes, preventive measures, and escalation patterns—essential for high-velocity teams in industries like aviation, manufacturing, and IT services. Let’s break them down with clarity and depth.

II. MTBF: Mean Time Between Failures – The Pillar of Reliability

MTBF measures the average time between consecutive failures in a repairable system, such as a hydraulic press or server rack. It’s a direct indicator of reliability and availability, with higher values signaling robust equipment. Originating from the aviation sector—where system failures pose life-or-death risks—MTBF has become a cornerstone in technical and mechanical industries, including Vietnam’s growing manufacturing hubs.

1. How to Calculate MTBF

The formula is simple yet powerful:

- MTBF = Total Operational Time / Number of Failures

Operational time excludes scheduled maintenance but includes all unexpected outages. For example, if a conveyor system runs for 8,760 hours in a year (24/7 operation) and experiences 10 failures, the MTBF is 8,760 / 10 = 876 hours. This means, on average, the system operates for 876 hours between failures.

2. Challenges in MTBF Calculation

- Data Availability: Incomplete logs can skew results.

- Constant Failure Rate Assumption: Many systems, especially complex ones, don’t fail at a steady rate—early wear or aging can distort MTBF.

- No Repair Time: MTBF ignores repair duration, focusing solely on failure intervals.

3. Why MTBF Matters

MTBF helps buyers select reliable equipment, like choosing a durable pump for a chemical plant, and aids internal teams in pinpointing issues. It’s ideal for developing maintenance schedules or recommending part replacements. For instance, a low MTBF on a motor might prompt a switch to a higher-quality model, reducing future downtime.

4. Practical Example

Imagine a packaging line with a labeling machine running 720 hours monthly, experiencing 3 failures. MTBF = 720 / 3 = 240 hours. The maintenance team could schedule checks every 200 hours to preempt failures, leveraging MTBF to optimize uptime.

III. MTTF: Mean Time to Failure – Predicting Non-Repairable Lifespan

MTTF tracks the average time a non-repairable component operates before failing completely, requiring replacement. Examples include LED lights, fuses, or certain circuit boards. This metric is crucial for understanding the expected lifespan of assets, aiding in lifecycle planning.

1. How to Calculate MTTF

The formula is:

- MTTF = Total Operating Time of All Units / Number of Failures

Consider testing 50 light bulbs, each running 1,000 hours, with 5 failing. Total operating time is 50,000 hours (50 x 1,000), and MTTF = 50,000 / 5 = 10,000 hours. This suggests each bulb lasts about 10,000 hours on average.

2. Challenges in MTTF Calculation

- Data Quality: Inconsistent failure data can lead to inaccurate predictions.

- Long Lifespan Limitations: For assets like tablets or heavy machinery meant to last years, short-term tests (e.g., 6 months) can overestimate MTTF. If 100 tablets run for 6 months (4,800 hours total) with 1 failure, MTTF = 4,800 / 1 = 4,800 hours (400 months or 33 years), which is unrealistic.

- No Repair Consideration: Like MTBF, it excludes repair time.

3. Why MTTF Matters

MTTF is perfect for short-lifespan items and helps plan replacements. In IT asset management, tracking MTTF for peripherals like keyboards ensures timely stock replenishment, reducing user disruptions. It also supports predictive maintenance by flagging when to replace aging components.

4. Practical Example

A factory tests 20 sensors, each running 500 hours, with 4 failures. Total time is 10,000 hours, so MTTF = 10,000 / 4 = 2,500 hours. The team can order replacements every 2,000 hours to avoid downtime.

IV. MTTR: Mean Time to Repair, Recovery, Respond, or Resolve – The Speed Metric

MTTR is a multifaceted metric with four interpretations, each focusing on a phase of incident response:

- Mean Time to Repair: Average time to fix and test a system, from failure detection to full operation.

- Mean Time to Recovery: Total downtime from failure to restored functionality, including all recovery steps.

- Mean Time to Respond: Time from alert to action start, excluding alert delays.

- Mean Time to Resolve: Full time to fix, prevent recurrence, and verify long-term stability.

1. How to Calculate MTTR

The general formula is:

- MTTR = Total Time Spent on the Process / Number of Incidents

- Repair Example: A server has 5 outages in a week, with 10 hours total repair time. MTTR (Repair) = 10 / 5 = 2 hours.

- Recovery Example: If each outage takes 3 additional hours to restore full service, total recovery time is 25 hours (5 x 5), so MTTR (Recovery) = 25 / 5 = 5 hours.

- Resolve Example: Adding 2 hours per incident for preventive measures (e.g., software patches), total resolve time is 35 hours, so MTTR (Resolve) = 35 / 5 = 7 hours.

2. Challenges in MTTR Calculation

- Inconsistent Data: Varying definitions of “repair” or “recovery” across teams can confuse metrics.

- Multiple Failures: Overlapping incidents complicate start/end times.

- Unstructured Support: Selective ticketing can skew data.

3. Why MTTR Matters

MTTR is a DevOps and IT service management (ITSM) favorite, measuring stability and customer satisfaction. A low MTTR (Repair) shows efficient fixes, while a low MTTR (Resolve) ensures long-term fixes, correlating with happier clients. It’s used in cybersecurity to neutralize attacks and in manufacturing to restore production lines swiftly.

4. Practical Example

A CNC machine fails 4 times in a month, with repairs taking 8 hours total (MTTR Repair = 8 / 4 = 2 hours) and recovery adding 4 hours per incident (total 16 hours, MTTR Recovery = 16 / 4 = 4 hours). The team can focus on speeding up diagnostics to lower MTTR.

V. MTTA: Mean Time to Acknowledge – The Response Trigger

MTTA measures the average time from incident detection to acknowledgment, reflecting team responsiveness and alert system effectiveness. It’s the first step in minimizing downtime.

How to Calculate MTTA

The formula is:

- MTTA = Total Time from Alert to Acknowledgment / Number of Incidents

If 3 incidents occur with acknowledgment times of 5, 10, and 15 minutes (total 30 minutes), MTTA = 30 / 3 = 10 minutes.

Challenges in MTTA Calculation

- Acknowledgment Definition: Teams must agree on what “acknowledge” means (e.g., ticket assignment).

- Evaluation Period: Short periods give quick feedback, but long periods offer stability.

- Alert Fatigue: Too many alerts can delay responses.

Why MTTA Matters

A low MTTA ensures fast incident initiation, boosting user satisfaction and escalation management. In cybersecurity, it tracks reaction speed to threats. It’s a vital sign of operational readiness, especially in 24/7 environments.

Practical Example

A power grid alerts 5 times in a day, with acknowledgment times of 2, 4, 6, 8, and 10 minutes (total 30 minutes). MTTA = 30 / 5 = 6 minutes. The team could implement automated alerts to reduce this further.

VI. What’s the Difference Between MTBF, MTTF, MTTR, and MTTA?

While these metrics are interrelated, they serve distinct purposes:

- MTBF vs. MTTF: MTBF applies to repairable systems (e.g., a pump that can be fixed), while MTTF is for non-repairable items (e.g., a fuse that needs replacing). Both assess reliability, but MTBF focuses on intervals between failures, and MTTF predicts total lifespan.

- MTTR vs. MTTA: MTTR measures the time to fix or recover from an incident, while MTTA tracks the initial acknowledgment. A low MTTA can lead to a lower MTTR by speeding up the response process.

- Holistic Insight: Together, these metrics paint a complete picture. MTBF and MTTF show reliability and lifespan, while MTTR and MTTA reveal response efficiency. For example, a high MTBF with a low MTTR indicates a reliable system with quick fixes, ideal for continuous operations.

Comparison Table of MTBF, MTTF, MTTR, and MTTA

|

Criteria |

MTBF (Mean Time Between Failures) |

MTTF (Mean Time to Failure) |

MTTR (Mean Time to Repair/Recovery/Respond/Resolve) |

MTTA (Mean Time to Acknowledge) |

|

Definition |

The average time between consecutive failures of a repairable system. |

The average time until a non-repairable system or component completely fails. |

The average time to repair, recover, respond, or resolve an incident (context-dependent). |

The average time from incident detection to its official acknowledgment. |

|

Calculation Formula |

MTBF = Total Operational Time / Number of Failures |

MTTF = Total Operating Time of All Units / Number of Failures |

MTTR = Total Time Spent on the Process (Repair/Recovery/Respond/Resolve) / Number of Incidents |

MTTA = Total Time from Alert to Acknowledgment / Number of Incidents |

|

Practical Applications |

Schedule preventive maintenance, select reliable equipment, monitor failure trends. |

Plan replacement of non-repairable components, manage asset lifecycle. |

Optimize repair processes, assess team efficiency, ensure SLA compliance. |

Evaluate team responsiveness, improve alert systems. |

|

Advantages |

Measures reliability of repairable systems, supports operational forecasting. |

Provides insight into expected asset lifespan, aids resource management. |

Assesses speed and efficiency of incident handling, enhances user experience. |

Ensures rapid initial response, reduces early downtime. |

|

Limitations |

Excludes repair time, assumes constant failure rate, requires accurate data. |

Less effective for long-lived assets, excludes repair time. |

Prone to confusion due to multiple definitions, depends on consistent data. |

Depends on “acknowledgment” definition, can be affected by alert fatigue. |

|

Relationship with Other Metrics |

High MTBF indicates high reliability, indirectly influences lower MTTR. |

High MTTF suggests long lifespan, supports MTBF in durability assessment. |

Low MTTR improves uptime, inversely related to MTBF and MTTF. |

Low MTTA leads to lower MTTR, initiates the response process. |

|

Applicable Industries |

Aviation, manufacturing, mechanical, IT. |

IT asset management, electronics manufacturing. |

DevOps, ITSM, cybersecurity, manufacturing. |

Cybersecurity, ITSM, 24/7 incident management. |

|

Optimization Goal |

Increase MTBF to reduce failure frequency. |

Increase MTTF to extend asset lifespan. |

Decrease MTTR to enhance recovery speed. |

Decrease MTTA to improve initial response time. |

VII. Practical Applications in Industrial Maintenance

From a maintenance expert’s viewpoint, these metrics guide strategic decisions:

- Preventive Maintenance: Use MTBF to schedule checks before failures occur, and MTTF to plan replacements for non-repairable parts.

- Response Optimization: Leverage MTTR to streamline repair processes and MTTA to enhance alert systems, reducing downtime in critical production areas.

- Cost Management: High MTBF and low MTTR can lower maintenance costs by minimizing unexpected breakdowns and repair times.

Consider a packaging line where a sensor fails every 500 hours (MTBF = 500 hours) and takes 2 hours to repair (MTTR = 2 hours). If acknowledgment takes 15 minutes (MTTA = 15 minutes), the team can use this data to prioritize sensor upgrades and faster alert responses, boosting overall efficiency.

VIII. Elevating Maintenance with CMMS EcoMaint

Managing these metrics manually can be daunting, but advanced solutions like CMMS EcoMaint from Vietsoft offer a game-changer. This software streamlines incident tracking, automates MTBF, MTTF, MTTR, and MTTA calculations, and provides actionable insights to optimize maintenance schedules. Curious about how CMMS EcoMaint can transform your operations? Learn more about CMMS EcoMaint here.

Contact us via hotline: 0986778578 or email: sales@vietsoft.com.vn.

IX. Conclusion

Mastering MTBF, MTTF, MTTR, and MTTA empowers maintenance professionals to enhance system reliability, respond swiftly to incidents, and minimize downtime. By integrating these metrics into your workflow—supported by tools like CMMS EcoMaint—you can build a resilient industrial operation that thrives in today’s competitive market. Start measuring these metrics today to unlock the full potential of your maintenance strategy.