In industrial maintenance and production management, optimizing equipment performance is critical to minimizing downtime and maximizing productivity. Two essential key performance indicators (KPIs) that help achieve these goals are Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR). These metrics provide deep insights into equipment reliability and maintenance efficiency, enabling businesses to make data-driven decisions. In this comprehensive guide, we’ll explore the differences between MTTR vs MTBF, their calculations, applications, and strategies to improve them, with a focus on practical insights for maintenance professionals in Vietnam’s industrial sector.

By understanding and leveraging these metrics, companies can reduce costly unplanned downtime, enhance operational efficiency, and stay competitive in the era of Industry 4.0. Let’s dive into the details of MTTR vs MTBF and how they shape modern maintenance practices.

I. What is Mean Time Between Failures (MTBF)?

1. Definition of MTBF

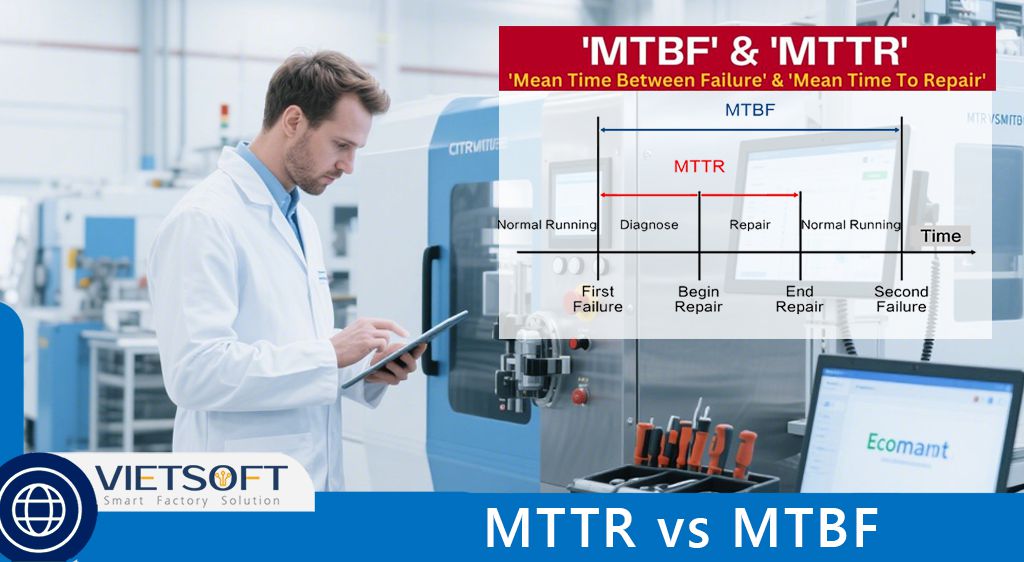

Mean Time Between Failures (MTBF) measures the average time a repairable system or piece of equipment operates before experiencing a failure. It’s a critical indicator of reliability, widely used in industries like manufacturing, IT, and facility management to assess how dependable an asset is. A higher MTBF indicates that equipment is more reliable and requires less frequent maintenance.

MTBF is distinct from Mean Time to Failure (MTTF), which applies to non-repairable items that must be replaced upon failure (e.g., light bulbs). For repairable assets like production machinery, MTBF is the go-to metric.

2. How to Calculate MTBF

The formula for MTBF is straightforward:

MTBF = Total operating time ÷ Number of failures

Example:

Suppose a packaging machine operates for 2,000 hours in a quarter and experiences 5 failures during that period. The MTBF calculation would be:

2,000 hours ÷ 5 failures = 400 hours.

This means, on average, the machine runs for 400 hours before a failure occurs.

3. Applications of MTBF in Maintenance

MTBF is a versatile metric with several practical applications:

- Reliability Assessment: A high MTBF indicates robust equipment, while a low MTBF signals frequent issues that may require design improvements or replacement.

- Maintenance Planning: By knowing the average time between failures, maintenance teams can schedule preventive maintenance just before a failure is likely, reducing unplanned downtime.

- Vendor Evaluation: When purchasing new equipment, comparing MTBF values helps identify more reliable options, saving costs in the long run.

- Cost Estimation: Low MTBF can lead to significant downtime costs. For instance, if a machine with an MTBF of 200 hours generates $1,000 per hour and fails for 2 hours each time, each failure costs $2,000 in lost production.

4. Limitations of MTBF

While MTBF is valuable, it has limitations:

- It doesn’t account for repair time, which can significantly impact downtime.

- It relies on historical data, so inaccurate or incomplete records can skew results.

- It’s less relevant for new equipment with no failure history.

II. What is Mean Time to Repair (MTTR)?

1. Definition of MTTR

Mean Time to Repair (MTTR), sometimes referred to as Mean Time to Recovery, measures the average time required to diagnose, repair, and restore a failed system or equipment to full operation. This metric reflects the efficiency of maintenance processes and the responsiveness of technical teams. A lower MTTR indicates faster repairs, minimizing production disruptions.

MTTR includes all activities from the moment a failure is detected to when the equipment is back online, such as troubleshooting, part replacement, reassembly, and testing.

2. How to Calculate MTTR

The MTTR formula is:

MTTR = Total downtime ÷ Number of repairs

Example:

Over a month, a conveyor belt fails 4 times, with repair times of 1 hour, 1.5 hours, 2 hours, and 0.5 hours. Total downtime is 1 + 1.5 + 2 + 0.5 = 5 hours. The MTTR calculation is:

5 hours ÷ 4 repairs = 1.25 hours.

On average, it takes 1.25 hours to repair the conveyor belt after a failure.

3. Applications of MTTR in Maintenance

MTTR is crucial for evaluating and improving maintenance operations:

- Maintenance Efficiency: A low MTTR reflects a skilled, well-prepared maintenance team and streamlined repair processes.

- Downtime Management: By tracking MTTR, managers can estimate production losses and plan schedules to account for repair times.

- Inventory Optimization: High MTTR due to unavailable spare parts highlights the need for better inventory management.

- Training Needs: If MTTR is high due to skill gaps, targeted training can improve technician performance.

4. Strategies to Reduce MTTR

To minimize MTTR, consider these approaches:

- Training Programs: Equip technicians with specialized skills for specific equipment to speed up diagnostics and repairs.

- Spare Parts Availability: Maintain an inventory of critical components to avoid delays waiting for parts.

- Standardized Procedures: Develop clear repair protocols to eliminate unnecessary steps and ensure consistency.

- Predictive Maintenance Tools: Use sensors and IoT devices to detect issues early, allowing repairs before complete failures occur.

III. MTTR vs MTBF: Key Differences

Understanding the distinction between MTTR vs MTBF is essential for effective maintenance management. Here’s a breakdown of their differences:

|

Metric |

Definition |

Focus |

Goal |

Example Use Case |

|

MTBF |

Average time between failures |

Equipment reliability |

Increase (higher is better) |

Schedule preventive maintenance for a CNC machine |

|

MTTR |

Average time to repair after a failure |

Maintenance efficiency |

Decrease (lower is better) |

Optimize repair processes for a hydraulic pump |

- MTBF answers: How long can we expect this equipment to run before it fails?

- MTTR answers: How quickly can we get this equipment back online after a failure?

While MTBF focuses on preventing failures, MTTR focuses on recovering from them. Both metrics are complementary and should be used together for a holistic view of asset performance.

IV. How MTBF and MTTR Work Together

Combining MTTR vs MTBF provides a comprehensive picture of equipment health and maintenance effectiveness. For example:

- In a manufacturing plant, a high MTBF (e.g., 500 hours) indicates reliable machinery, while a low MTTR (e.g., 2 hours) ensures quick recovery from failures, maximizing uptime.

- In IT systems, MTBF helps assess software stability (e.g., time between crashes), while MTTR measures how fast developers can deploy fixes, reducing service disruptions.

Real-World Example

Consider two machines in a factory:

- Machine A: MTBF = 600 hours, MTTR = 3 hours

- Machine B: MTBF = 200 hours, MTTR = 8 hours

Machine A is preferable because it fails less often (every 600 hours vs. 200 hours) and is repaired faster (3 hours vs. 8 hours). This results in less downtime and lower costs. By analyzing both metrics, managers can prioritize investments in reliable equipment and streamline repair processes.

VI. Impact on Downtime and Costs

Downtime is a function of both MTBF and MTTR. The formula for availability (the percentage of time equipment is operational) is:

Availability = MTBF ÷ (MTBF + MTTR)

Example:

For Machine A (MTBF = 600 hours, MTTR = 3 hours):

Availability = 600 ÷ (600 + 3) = 99.5%.

For Machine B (MTBF = 200 hours, MTTR = 8 hours):

Availability = 200 ÷ (200 + 8) = 96.15%.

Machine A’s higher availability translates to more production time and lower losses.

VI. Strategies to Improve MTBF and MTTR

Improving MTTR vs MTBF requires a strategic approach to maintenance and asset management. Here are actionable tips:

1. Improving MTBF

· Invest in Quality Equipment: Choose machines with proven high MTBF from reputable suppliers.

· Preventive Maintenance: Schedule regular inspections and part replacements based on MTBF data to prevent failures.

· Operator Training: Train staff to use equipment correctly, reducing wear and tear.

· Upgrade Components: Replace low-quality or worn parts with durable alternatives to extend equipment life.

2. Reducing MTTR

· Real-Time Monitoring: Use IoT sensors to detect issues early, reducing diagnostic time.

· Maintenance Software: Implement a Computerized Maintenance Management System (CMMS) to streamline work orders, track repairs, and manage spare parts.

· Skilled Workforce: Hire experienced technicians and provide ongoing training.

· Pre-Prepared Kits: Keep repair kits with tools and parts ready for common failures.

VII. Role of CMMS in Optimizing MTBF and MTTR

A CMMS like EcoMaint from Vietsoft revolutionizes maintenance management by automating processes and providing real-time insights. Key features include:

- Preventive Maintenance Scheduling: Automatically schedules maintenance tasks based on MTBF trends, preventing failures.

- Work Order Management: Assigns and tracks repair tasks, reducing MTTR by ensuring quick responses.

- Inventory Control: Tracks spare parts, ensuring availability to minimize repair delays.

- Data Analytics: Generates reports on MTBF and MTTR, helping managers identify trends and optimize strategies.

By integrating CMMS EcoMaint, businesses in Vietnam can achieve higher equipment reliability and faster repairs, driving operational excellence. Curious about how CMMS EcoMaint can transform your maintenance processes? Learn more about CMMS EcoMaint here.

Contact us via hotline: 0986778578 or email: sales@vietsoft.com.vn.

VIII. Common Challenges in Managing MTTR and MTBF

Despite their benefits, tracking and improving MTTR vs MTBF can present challenges:

1. Data Accuracy: Inaccurate failure or repair logs can distort metrics. Solution: Use a CMMS to automate data collection.

2. Resource Constraints: Limited budgets or staff can hinder improvements. Solution: Prioritize high-impact equipment based on MTBF and MTTR analysis.

3. Complex Systems: Multi-component systems may have varying MTBF and MTTR values. Solution: Break down metrics by component for targeted improvements.

4. Resistance to Change: Staff may resist new processes or tools. Solution: Provide training and demonstrate the benefits of improved metrics.

IX. Industry 4.0 and the Future of MTTR and MTBF

In the era of Industry 4.0, technologies like IoT, AI, and big data are transforming how MTTR vs MTBF are managed. Predictive maintenance, powered by AI-driven analytics, uses real-time data to forecast failures, boosting MTBF and reducing MTTR. For example:

- IoT Sensors: Monitor equipment health, alerting technicians to potential issues before failures occur.

- AI Analytics: Analyze historical MTBF and MTTR data to predict future trends and optimize maintenance schedules.

- Digital Twins: Simulate equipment performance to test maintenance strategies without risking downtime.

By adopting these technologies, Vietnamese manufacturers can stay ahead in a competitive market, ensuring high reliability and minimal downtime.

X. Practical Tips for Vietnamese Manufacturers

For maintenance professionals in Vietnam, here are tailored tips to leverage MTTR vs MTBF:

1. Start Small: Begin tracking MTBF and MTTR for critical equipment to build a data foundation.

2. Use Local Context: Account for Vietnam’s humid climate or power fluctuations, which may affect equipment reliability.

3. Engage Teams: Involve operators and technicians in data collection to ensure accuracy and buy-in.

4. Adopt Technology: Invest in affordable CMMS solutions like EcoMaint to automate and scale maintenance efforts.

XI. Conclusion: Mastering MTTR vs MTBF for Operational Excellence

MTTR vs MTBF are indispensable metrics for any industrial operation aiming to reduce downtime, optimize maintenance, and boost productivity. By understanding their differences—MTBF for reliability and MTTR for repair efficiency—maintenance teams can develop targeted strategies to improve both. Combining these metrics with modern tools like EcoMaint CMMS empowers businesses to achieve higher availability, lower costs, and a competitive edge in Vietnam’s industrial landscape.