Risk-based Maintenance (RbM) is a strategic methodology that revolutionizes how industries manage asset maintenance by prioritizing resources based on the risk of equipment failure. Unlike traditional approaches that rely on fixed schedules or reactive repairs, RbM uses data-driven risk assessments to focus maintenance efforts on assets that pose the greatest threat to safety, production, or financial stability.

This guide provides a detailed exploration of Risk-based Maintenance (RbM), its principles, benefits, implementation steps, and key performance indicators, offering actionable insights for maintenance professionals in Vietnam and beyond to apply RbM effectively in practice.

I. Understanding Risk-based Maintenance (RbM)

Risk-based Maintenance (RbM) is a maintenance strategy that optimizes resource allocation by evaluating the likelihood and consequences of equipment failure. It involves identifying critical assets, assessing their risk profiles, and tailoring maintenance plans to minimize the impact of failures. By focusing on high-risk assets, RbM ensures that maintenance efforts are both cost-effective and aligned with operational priorities.

In Vietnam’s rapidly growing industrial sector, where manufacturing, logistics, and infrastructure are key drivers, RbM is particularly valuable. It helps companies reduce downtime, comply with stringent regulations, and optimize limited maintenance budgets. For example, a manufacturing plant can use RbM to prioritize maintenance on critical production lines, ensuring uninterrupted output while minimizing unnecessary work on low-risk equipment.

II. Why Risk-based Maintenance Matters

Unplanned equipment failures can have severe consequences, with studies estimating downtime costs in manufacturing at up to $250,000 per hour. RbM mitigates these risks by directing maintenance efforts toward assets with the highest potential impact. This approach not only reduces downtime but also enhances safety, improves compliance, and extends asset lifespan, making it a critical tool for industries aiming to stay competitive.

Moreover, RbM aligns maintenance with business objectives, such as cost control, safety, and environmental responsibility. In Vietnam, where industrial regulations are tightening, RbM enables companies to meet compliance standards while optimizing resource use, providing a strategic advantage in a dynamic market.

III. Core Principles of Risk-based Maintenance

Risk-based Maintenance (RbM) is grounded in three key principles that ensure its effectiveness:

1. Risk Assessment

The foundation of RbM is a systematic evaluation of each asset’s risk, based on two factors:

- Probability of Failure (PoF): The likelihood of an asset failing, influenced by its age, condition, usage, and environmental factors (e.g., humidity or dust in Vietnam’s industrial settings).

- Consequence of Failure (CoF): The impact of failure on safety, production, costs, or regulatory compliance.

The risk is calculated as:

Risk = Probability of Failure (PoF) × Consequence of Failure (CoF)

This formula quantifies the risk level, guiding maintenance prioritization.

2. Criticality Ranking

Assets are ranked based on their risk scores. High-risk assets, such as a primary boiler critical to production, receive more frequent maintenance, while low-risk assets, like secondary pumps, may follow less intensive schedules. This ranking ensures that maintenance aligns with operational priorities.

3. Resource Optimization

RbM optimizes the use of time, labor, and budget by focusing on high-risk assets. This reduces unnecessary maintenance on low-risk equipment, freeing up resources for critical tasks and improving overall efficiency.

These principles make RbM a strategic tool that enhances reliability while minimizing waste, particularly in resource-constrained environments like Vietnam’s industrial sector.

Benefits of Risk-based Maintenance

Implementing Risk-based Maintenance (RbM) offers significant advantages for industrial operations, especially when supported by tools like Vietsoft’s CMMS EcoMaint. Below are the key benefits, explained in detail:

1. Maximized Resource Allocation

RbM ensures that maintenance resources—labor, parts, and budget—are directed toward assets with the highest risk. For example, a factory can prioritize a critical conveyor system over a backup generator, optimizing manpower and reducing wasteful spending.

2. Reduced Downtime

By proactively addressing high-risk assets, RbM minimizes unplanned downtime. A chemical plant in the Gulf Coast, for instance, reduced maintenance costs by $3.2 million annually using RbM, demonstrating its impact on operational continuity.

3. Enhanced Safety

RbM prioritizes assets with significant safety implications, such as fire suppression systems or high-pressure vessels. By addressing potential failures early, it reduces the risk of accidents, protecting workers and ensuring compliance with Vietnam’s safety regulations.

4. Cost Efficiency

RbM eliminates unnecessary maintenance on low-risk assets, lowering costs. A study by Aalborg University found that RbM reduced repair costs by over 80% for offshore steel structures, showcasing its potential for significant savings.

5. Improved Regulatory Compliance

By focusing on assets critical to environmental or regulatory standards, RbM helps companies avoid penalties and maintain compliance, a key consideration in Vietnam’s increasingly regulated industrial landscape.

6. Extended Asset Lifespan

Proactive maintenance of high-risk assets extends their operational life, delaying costly replacements. For example, regular monitoring of a critical pump can prevent wear, adding years to its service life.

IV. Steps to Implement Risk-based Maintenance

Implementing Risk-based Maintenance (RbM) requires a structured, data-driven approach. Below is a detailed, step-by-step guide designed to equip maintenance teams with the practical knowledge needed to apply RbM effectively. Each step includes actionable methods, formulas, and implementation strategies.

1. Step 1: Collect Comprehensive Asset Data

Purpose: Gather accurate data to assess asset risk and inform maintenance decisions.

How to Execute:

- Compile a detailed inventory of all assets, including name, type, serial number, and location.

- Collect data on:

- Acquisition Cost: Initial cost of the asset.

- Age and Condition: Current operational state and usage history.

- Mean Time Between Failures (MTBF): Average time between failures, calculated as:

MTBF = Total Operating Time ÷ Number of Failures

Example: A motor operates for 15,000 hours and fails 3 times. MTBF = 15,000 ÷ 3 = 5,000 hours. - Mean Time to Repair (MTTR): Average time to restore functionality, calculated as:

MTTR = Total Repair Time ÷ Number of Repairs

Example: A pump requires 12 hours total to repair over 3 incidents. MTTR = 12 ÷ 3 = 4 hours. - Downtime Costs: Financial impact of failures, including lost production and labor costs.

- Maintenance Frequency: How often the asset is serviced, tracked via work order logs.

- Use a CMMS like Vietsoft’s CMMS EcoMaint to centralize data collection, automate updates, and integrate real-time sensor data (e.g., vibration or temperature readings).

Practical Tip: Start with high-value or critical assets to build a robust dataset. If data is limited, use manufacturer specifications or industry benchmarks as initial estimates, refining them as more data is collected.

2. Step 2: Conduct a Criticality Analysis

Purpose: Identify assets with the highest impact on operations, safety, and costs.

How to Execute:

- Use a criticality matrix to evaluate assets across multiple dimensions:

- Safety Impact: Rate from 1 (minimal risk) to 5 (severe risk, e.g., potential fatalities).

- Production Impact: Rate from 1 (no disruption) to 5 (halts production).

- Financial Impact: Rate from 1 (low cost) to 5 (high repair/downtime costs).

- Environmental Impact: Rate from 1 (no impact) to 5 (significant pollution or regulatory violations).

- Calculate the Asset Criticality Rating (ACR) by summing or multiplying scores. For simplicity, use the sum:

ACR = Safety + Production + Financial + Environmental

Example: A boiler with scores of Safety = 4, Production = 5, Financial = 4, Environmental = 3 has an ACR of 4 + 5 + 4 + 3 = 16. - Alternatively, take the highest score in any category for a conservative approach (e.g., ACR = 5 for the boiler above).

Practical Tip: Engage cross-functional teams (operations, safety, engineering) to ensure accurate ratings. Use CMMS EcoMaint to store and visualize criticality data, enabling easy updates as conditions change.

3. Step 3: Assess Failure Likelihood

Purpose: Determine the probability of asset failure to quantify risk.

How to Execute:

- Rate the Probability of Failure (PoF) on a scale of 1 to 5:

- 1 = Very unlikely (fails less than once every 2 years).

- 2 = Unlikely (fails less than once per year).

- 3 = Occasional (fails 1–2 times per year).

- 4 = Likely (fails more than twice per year).

- 5 = Frequent (fails regularly).

- Base ratings on:

- Historical failure data from CMMS (e.g., MTBF).

- Real-time condition monitoring (e.g., vibration or temperature anomalies).

- Environmental factors (e.g., Vietnam’s humid climate accelerating corrosion).

- Example: A pump in a corrosive environment fails twice yearly, earning a PoF of 4.

Practical Tip: Use IoT sensors integrated with CMMS EcoMaint to monitor real-time conditions, improving PoF accuracy. Regularly update ratings based on new failure data.

4. Step 4: Calculate Risk Priority Number (RPN)

Purpose: Quantify risk to prioritize maintenance tasks.

How to Execute:

- Calculate the Risk Priority Number (RPN) using:

RPN = ACR × PoF

Example: For the boiler (ACR = 16, PoF = 4), RPN = 16 × 4 = 64 (High Risk).

For a low-risk HVAC unit (ACR = 3, PoF = 2), RPN = 3 × 2 = 6 (Low Risk). - Advanced method: Include a Detection Rating (DR) to account for the likelihood of detecting a failure before it occurs (1 = easily detectable, 5 = difficult).

RPN = ACR × PoF × DR

Example: If the boiler’s failure is hard to detect (DR = 4), RPN = 16 × 4 × 4 = 256.

Practical Tip: Use a CMMS to automate RPN calculations and generate risk reports, ensuring consistency and scalability across large asset portfolios.

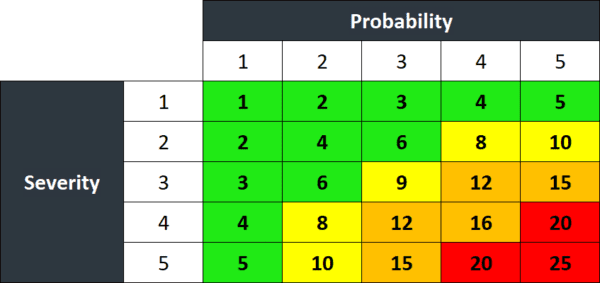

5. Step 5: Analyze and Prioritize Using a Risk Matrix

Purpose: Visualize and categorize risks to guide maintenance planning.

How to Execute:

- Create a risk matrix with PoF on the x-axis (1–5) and ACR on the y-axis (1–20 or higher, depending on the scoring method).

- Categorize RPN scores:

- Green (RPN < 20): Low risk, routine monitoring or run-to-failure.

- Yellow (RPN 20–50): Medium risk, schedule preventive maintenance.

- Red (RPN > 50): High risk, prioritize immediate action (e.g., condition-based or predictive maintenance).

- Example: The boiler (RPN = 64) falls in the red zone, requiring frequent monitoring, while the HVAC unit (RPN = 6) is in the green zone, needing only periodic checks.

Practical Tip: Use CMMS EcoMaint’s visualization tools to generate risk matrices, making it easy to share priorities with stakeholders and adjust plans dynamically.

6. Step 6: Develop a Risk Mitigation Plan

Purpose: Create a tailored maintenance strategy based on risk priorities.

How to Execute:

- Assign maintenance strategies based on RPN:

- High Risk (RPN > 50): Use Condition-based Maintenance (CbM) or Predictive Maintenance (PdM) with real-time monitoring (e.g., sensors for vibration or temperature).

- Medium Risk (RPN 20–50): Schedule Preventive Maintenance (PM) at regular intervals (e.g., quarterly inspections).

- Low Risk (RPN < 20): Apply Corrective Maintenance (CM) or run-to-failure strategies.

- Consider factors like:

- Manufacturer Recommendations: Follow OEM guidelines for maintenance intervals.

- Resource Availability: Allocate skilled technicians to high-risk assets.

- Cost-Benefit Analysis: Compare maintenance costs to downtime or replacement costs.

- Example: For a high-risk boiler (RPN = 64), implement weekly CbM with vibration sensors and schedule predictive maintenance based on data trends.

Practical Tip: Use CMMS EcoMaint to automate maintenance scheduling and assign tasks based on risk priorities, ensuring efficient resource allocation.

7. Step 7: Monitor and Continuously Improve

Purpose: Ensure RbM remains effective as assets and conditions evolve.

How to Execute:

- Conduct quarterly reviews to update ACR, PoF, and RPN based on new data (e.g., recent failures or sensor readings).

- Use Root Cause Analysis (RCA) to investigate failures and refine risk models. For example, if a pump fails due to bearing wear, adjust maintenance to include more frequent lubrication.

- Train teams on RbM methodologies and CMMS tools to enhance adoption and accuracy.

- Example: After addressing a high-risk conveyor (RPN = 50), reassess its risk after three months. If MTBF improves, adjust its PoF and maintenance frequency accordingly.

Practical Tip: Leverage CMMS EcoMaint’s reporting features to track improvements, generate trend analyses, and schedule automated risk reassessments.

V. Key Performance Indicators (KPIs) for Risk-based Maintenance

Tracking KPIs is essential to measure the effectiveness of Risk-based Maintenance (RbM) and ensure it delivers tangible results. Below are the most critical KPIs, with detailed explanations, formulas, and practical applications to help maintenance teams monitor and optimize their RbM strategy.

1. Mean Time Between Failures (MTBF)

Definition: The average time an asset operates before failing, indicating reliability.

Formula:

MTBF = Total Operating Time ÷ Number of Failures

Example: A compressor operates for 20,000 hours and fails 4 times. MTBF = 20,000 ÷ 4 = 5,000 hours.

Application:

- Track MTBF for high-risk assets to assess whether RbM increases reliability.

- Compare MTBF across asset classes to identify outliers needing attention.

- Example: If a boiler’s MTBF increases from 5,000 to 7,000 hours after implementing RbM, it indicates improved reliability.

Practical Tip: Use CMMS EcoMaint to automate MTBF calculations by tracking failure events and operating hours in real time.

2. Mean Time to Repair (MTTR)

Definition: The average time required to restore an asset after a failure, reflecting maintenance efficiency.

Formula:

MTTR = Total Repair Time ÷ Number of Repairs

Example: A pump requires 15 hours total to repair over 3 incidents. MTTR = 15 ÷ 3 = 5 hours.

Application:

- Monitor MTTR for high-risk assets to ensure rapid response to failures.

- Reduce MTTR by prioritizing skilled technicians and spare parts for critical assets.

- Example: If MTTR for a critical conveyor decreases from 6 to 4 hours, RbM is improving repair efficiency.

Practical Tip: CMMS EcoMaint tracks repair times and generates MTTR reports, helping identify bottlenecks in maintenance workflows.

3. Unplanned Downtime Costs

Definition: The financial impact of unexpected failures, including lost production, labor, and repair costs.

Formula:

Downtime Cost = (Lost Production Hours × Cost per Hour) + Repair Costs

Example: A production line downtime of 2 hours at $10,000/hour plus $2,000 in repairs = (2 × 10,000) + 2,000 = $22,000.

Application:

- Track downtime costs for high-risk assets to quantify RbM’s financial impact.

- Use reductions in downtime costs to justify RbM investments.

- Example: A factory reducing downtime costs from $500,000 to $300,000 annually demonstrates RbM’s ROI.

Practical Tip: CMMS EcoMaint’s cost-tracking features calculate downtime costs automatically, linking them to specific assets and failures.

4. Maintenance Cost per Asset

Definition: The cost of maintaining an asset, including labor, parts, and overhead.

Formula:

Maintenance Cost per Asset = Total Maintenance Costs ÷ Number of Assets

Example: A factory spends $100,000 on maintenance for 50 assets. Maintenance Cost per Asset = 100,000 ÷ 50 = $2,000.

Application:

- Compare costs across high- and low-risk assets to ensure alignment with risk priorities.

- Reduce costs for low-risk assets by minimizing unnecessary maintenance.

- Example: If maintenance costs for low-risk assets drop by 20%, RbM is optimizing resource allocation.

Practical Tip: Use CMMS EcoMaint to categorize maintenance costs by asset risk level, ensuring efficient budgeting.

5. Work Order Backlog by Risk Level

Definition: The number of pending maintenance tasks, prioritized by risk.

Formula:

Work Order Backlog = Number of Open Work Orders (by Risk Category)

Example: 10 high-risk, 15 medium-risk, and 20 low-risk open work orders.

Application:

- Ensure high-risk work orders are completed first to minimize critical failures.

- Monitor backlog trends to allocate resources effectively.

- Example: Reducing high-risk backlog from 15 to 5 work orders indicates improved prioritization.

Practical Tip: CMMS EcoMaint automates work order prioritization based on RPN, ensuring high-risk tasks are addressed promptly.

6. Preventive Maintenance Compliance

Definition: The percentage of scheduled preventive maintenance tasks completed on time for high-risk assets.

Formula:

PM Compliance = (Completed PM Tasks ÷ Scheduled PM Tasks) × 100

Example: 90 out of 100 scheduled PM tasks completed on time = (90 ÷ 100) × 100 = 90%.

Application:

- Track compliance to ensure high-risk assets receive timely maintenance.

- Improve compliance by automating reminders and scheduling with a CMMS.

- Example: Increasing PM compliance from 80% to 95% for critical assets reduces failure risks.

Practical Tip: CMMS EcoMaint sends automated alerts for upcoming PM tasks, improving compliance rates.

VI. Integrating CMMS EcoMaint for Risk-based Maintenance

Vietsoft’s CMMS EcoMaint is a powerful tool for implementing Risk-based Maintenance (RbM) in Vietnam’s industrial sector. Its features streamline RbM processes and enhance decision-making:

- Asset Management: Centralizes data on MTBF, MTTR, and maintenance history, enabling accurate risk assessments.

- Automated Work Orders: Prioritizes tasks based on RPN, ensuring high-risk assets are addressed first.

- Real-time Analytics: Integrates with IoT sensors to monitor asset conditions and predict failures.

- Reporting Tools: Tracks KPIs like downtime costs, MTBF, and PM compliance, supporting continuous improvement.

By leveraging CMMS EcoMaint, companies can transition from reactive to proactive maintenance, reducing costs and enhancing reliability. Curious about how CMMS EcoMaint can optimize your RbM strategy? Learn more about CMMS EcoMaint here.

Contact us for consultation via hotline: 0986778578 or email: sales@vietsoft.com.vn.

VII. Best Practices for Risk-based Maintenance

To ensure RbM delivers maximum value, follow these best practices:

- Focus on High-risk Assets: Prioritize assets with the highest RPN for intensive monitoring and maintenance.

- Leverage Real-time Data: Use IoT sensors and CMMS EcoMaint to update risk profiles dynamically.

- Engage Cross-functional Teams: Involve operations, safety, and engineering for comprehensive risk assessments.

- Establish Clear Thresholds: Define RPN thresholds (e.g., >50 for immediate action) to trigger maintenance automatically.

- Train Staff: Provide training on RbM methodologies and CMMS tools to enhance adoption.

- Review Regularly: Update risk profiles quarterly or after incidents to reflect changing conditions.

VIII. Conclusion: The Future of Maintenance with RbM

Risk-based Maintenance (RbM) is a transformative approach that enables industries to optimize maintenance, reduce downtime, and enhance safety. By prioritizing high-risk assets and leveraging data-driven insights, RbM aligns maintenance with business goals, delivering significant cost savings and operational efficiency. In Vietnam’s competitive industrial landscape, RbM is a critical tool for staying ahead.

Vietsoft’s CMMS EcoMaint empowers maintenance teams to implement RbM effectively, with robust features for data management, risk prioritization, and analytics. Ready to revolutionize your maintenance strategy? Discover how CMMS EcoMaint can transform your operations.